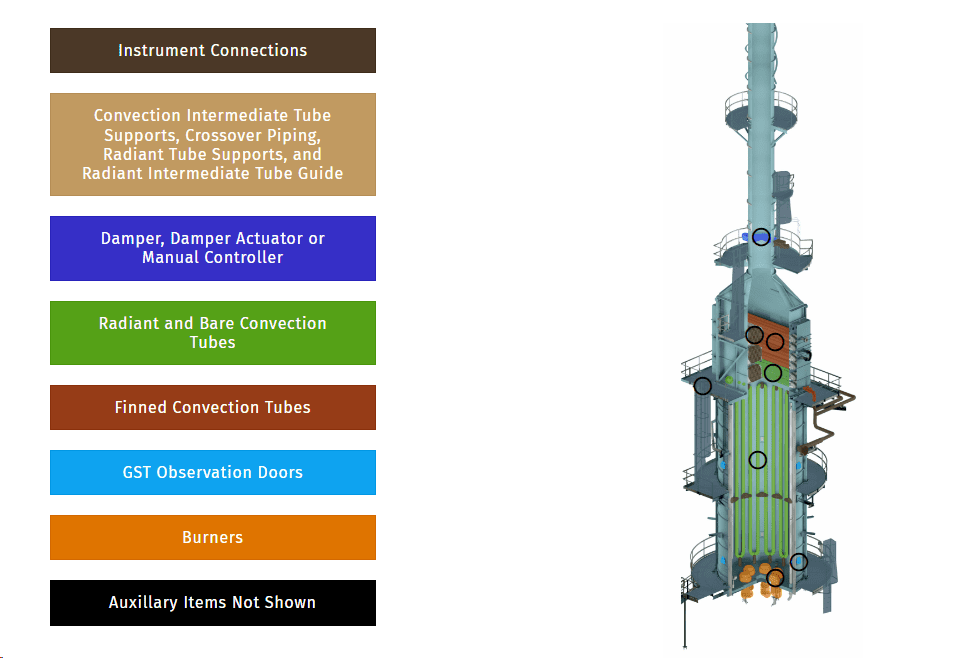

A Technical & Service Driven Heater Company

Great Southern Technologies (GST), an InServ Company, is a specialty engineering company that encompasses unique creative & custom design methodologies to improve direct fired heaters and auxiliary equipment. GST incorporates optimal constructability methods for every project, allowing for minimum turnaround duration and cost. The integrated concept that makes up InServʼs core business objective affords the ability to provide the client a single source from concept to installation. This reduces potential problems during installation and eliminates the risk of back charges.

What Our Great Southern Technologies

Heater Team Can Do:

New API-560 Direct Fired Heaters

GST is able to design, engineer, fabricate, and install the majority of combustion heat transfer equipment utilized by the refinery and petro-chemical industry. With strong expertise in manufacturing and construction, optimized fabrication techniques are applied that result in minimal field installation cost and schedule. In addition, extensive performance studies have paved the way for innovative and unmatched process design techniques and solutions.

safety driven company

Great Southern Technologies continues to focus on safety. Our expectation is to be incident free on every job.

safety driven company

Great Southern Technologies continues to focus on safety. Our expectation is to be incident free on every job.

Field Studies

Through countless heater evaluations, GST has developed proprietary software that allows us the ability to incorporate state of the art engineered solutions to all process heaters, including black oil services such as Crude, Vacuum, Cokers, and Visbreakers.

Schedule a Call

Fill out the form below to request a call and explore the capabilities of our divisions for your next project.